What are the welding advantages of Lansu laser welding machine?

What are the welding advantages of Lansu laser welding machine?

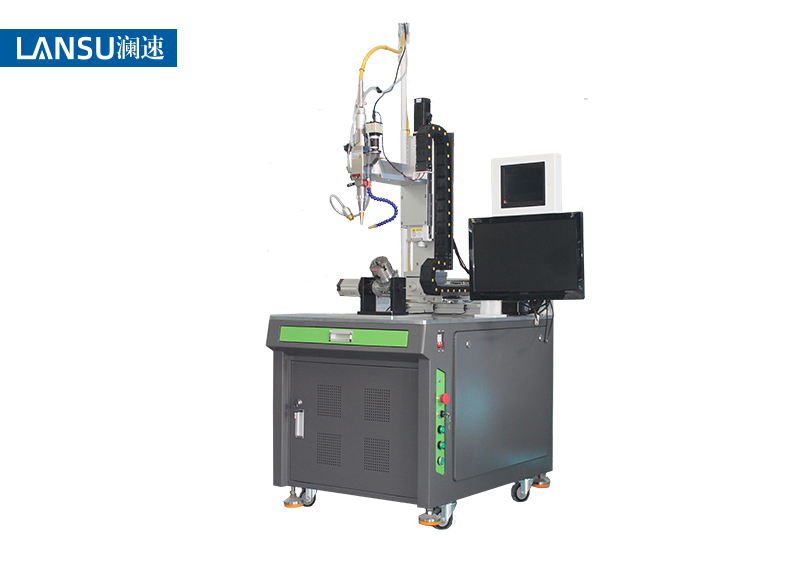

Laser welding machine, as its name implies, is a machine used for welding with laser materials. It is also often called laser welding machine and laser welding machine. It uses high-energy laser pulses to locally heat the material in a small area. Heat conduction diffuses to the interior of the material, and the material is melted to form a specific molten pool to achieve the purpose of welding.

1. The laser welding machine can weld refractory materials such as titanium and quartz, and can weld opposite materials with good results. Two metals can be laser welded with different physical properties. It is suitable for various materials and can be connected with different materials.

2. Fully automatic laser welding machine, which can be controlled by digital or computer.

3. It is characterized by a small heat-affected zone, narrow welds, fast cooling of welds, small changes in weld metal properties, and hard welds.

4. The laser welding machine is more environmentally friendly and energy-saving, and there is no concern about environmental pollution or damage. And because it is not a contact welding process, the wear and deformation of the machine can be reduced.

5. Due to the low heat input during laser welding, the amount of deformation after welding is small, and the welding effect of the surface is very beautiful, so the subsequent processing of laser welding is very small, which can greatly reduce or eliminate the huge polishing and finishing. Labor on leveling process.

6, laser welding machine can be micro-welded. The laser beam is focused to obtain a small spot, focused on a small area, suitable for welding small internal parts. And it can be accurately positioned, and can be applied to mass welding of a large number of small and small workpieces produced automatically.

For most electromechanical manufacturing industries, because modern laser welding systems can easily weld workpieces of different shapes and sizes, it is often preferred over die-cutting and stamping processes; although the processing speed of metal laser welding machines is still slower than that of die However, it has no mold consumption, no need to repair molds, and can save mold replacement time, which saves the processing costs of the enterprise and reduces the production cost of the enterprise, so it is more cost-effective in general.